In mining, bulk ore sorting is a pre-concentration technology that can be used to remove waste rock from ore before it enters the mill. Ore properties are measured using specialized sensors as it is mined or while it is on a conveyor. Measurements made with bulk ore sorting technology can then be used to support a variety of interrelated purposes, including grade control, ore digitization, real-time ore quality assessment, improved stockpiling, blending, and mine-to-mill reconciliation.

Bulk ore sorting technology can be configured with one or more ore sensors in a variety of form factors. The essential components of a bulk ore sorting system are an integrated sensor and diverter system which permits the routing or physical separation of the ore stream based on the properties measured by the sensor. Additional equipment and infrastructure may be required, depending on the installation type, such as crushers, apron feeders, sizers, and a sorting plant. This post provides a brief overview of bulk ore sorting sensors and system configurations.

What is the best sensor for my ore?

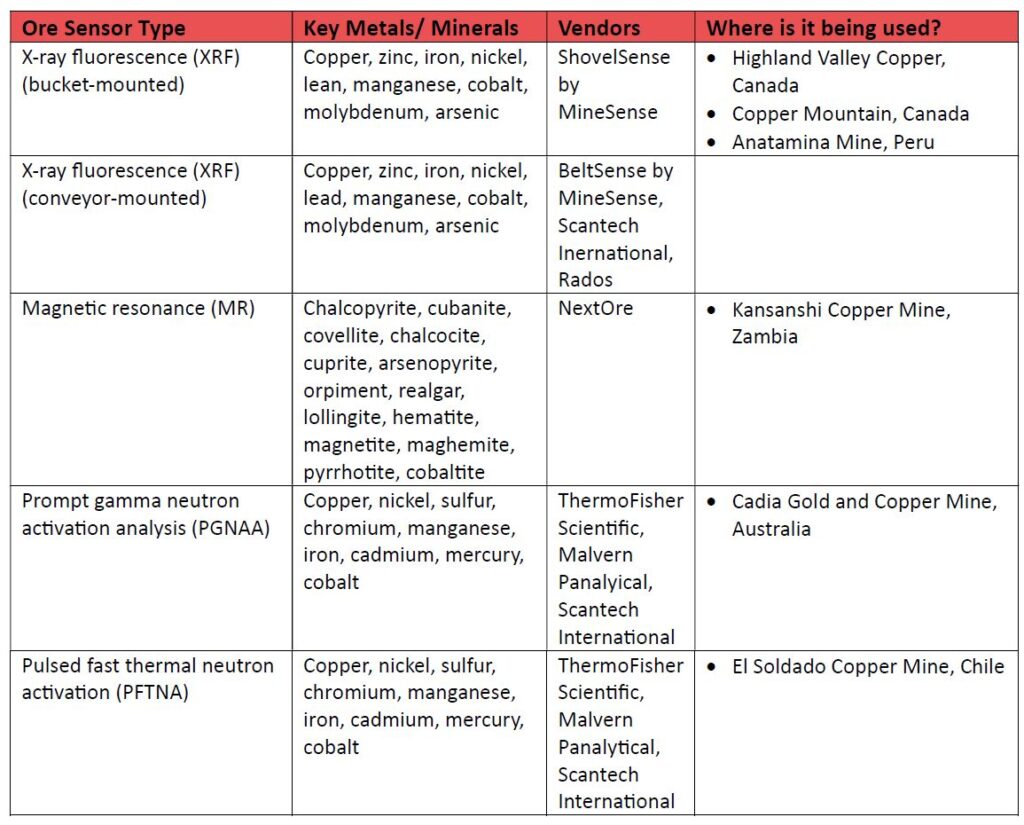

Currently, bulk ore sorting is best suited for based metals. To date, there is no reliable, high-throughput, industrial scale sensor for gold. However, the application of multi-elemental sensors for gold ore classification is a promising option and can be evaluated using machine learning analysis in a desktop study or through test work.

Here’s a breakdown of the most popular bulk ore sorting sensor types, metals and minerals they measure at high or very high detectability and high throughput, which companies offer the technology and an example of where the technology has or is currently being used.

Where can bulk ore sorting equipment be deployed in the mine?

Bulk ore sorting technology may be deployed at the extraction face, as part of an in-pit crush and convey system, on run-of-mine ore, or after a primary, secondary, or tertiary crusher before entering the mill. With ShovelSense by MineSense, sensing and sorting occur directly at the mine face. X-ray fluorescence (XRF) sensors are installed on the shovel or bucket loading equipment in the ShovelSense system and a measurement for each bucketload (25 to 80 tonnes) of ore can be made. In mid-2023, MMD announced successful trials of their fully mobile iFMSL system which permits sensing and diversion on the truck scale (120 to 240 tonnes) at the extraction face. In the iFMSL system, ore is loaded by a shovel into the surge bin, then a hopper distributes the ore as required to waiting trucks via a short conveyor that contains the ore sensor. To date the iFMSL system has been used with XRF, PGNAA, and PFTNA, although the iFMSL is sensor-agnostic and could be combined with other sensor types.

Semi-mobile and stationary bulk sorting systems are also available. In these systems, material may be loaded onto a conveyor belt at an apron feeder or as the underflow of a primary, secondary, or tertiary crusher. A physical separation of the ore feed is made into two piles or streams by changing the direction of an inclined conveyor.

Conclusion

This post described the most common bulk ore sensors and technology configurations. Assessing which is best for your operation depends on many factors, including the deposit mineralogy, ore grade heterogeneity, location of installation, and the intended use case.

At OrePortal, the evaluation of sensors and sensing system is part of our approach to using four pillars to assess the sortability of an ore deposit, which includes evaluation of: ore grade heterogeneity, available sensors, sensor configurations, and economic viability. Contact us for a detailed review and analysis of the viability of ore sorting in your project.